Areas of expertise

We can assist in all phases of diffusion coating application - including assistance in setting up a noble metal (Platinum) plating facility as well as the thermal processing needs for diffusion of Aluminum, Chromium and Silicon. These can be accomplished using either CVD (Chemical Vapor Deposition), Pack (where the part is essentially buried in the aluminum, chrome or silicon bearing precursors with a predominance of an inert material such as alumina "sand" and a activator, as well as another process called "atp" or "above the pack" gas phase diffusion coating.

Send an email to AMC

Advantagesof CVD and Gas Phase

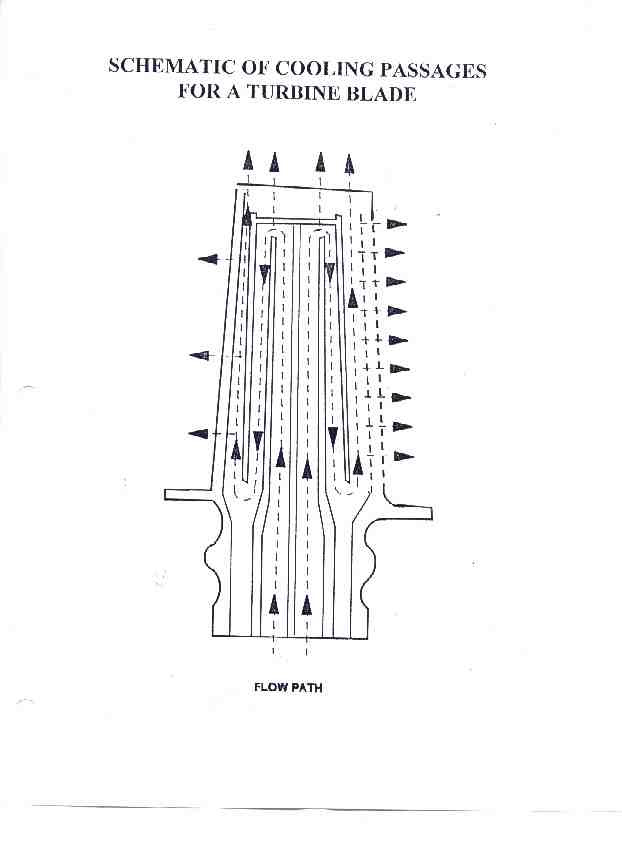

To coat the "internals" of components - both blades and vanes, gases can be generated in numerous ways and then passed into the component - and given the correct conditions of time, temperature and gas concentration can result in the desired element(s) diffusing into the component. |

Blade Design Showing Intricate Passages

AMC's Home Page |