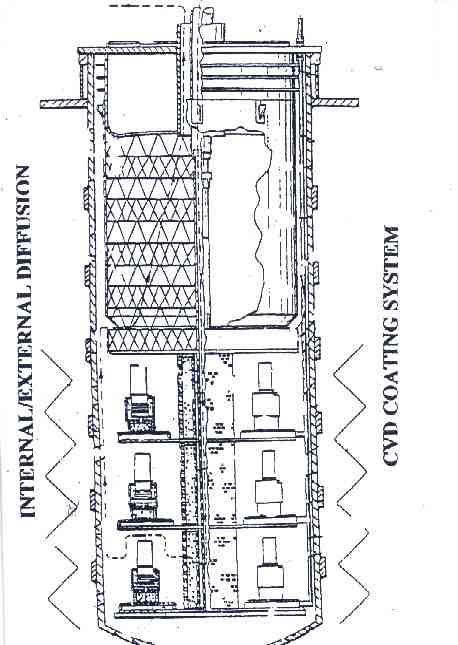

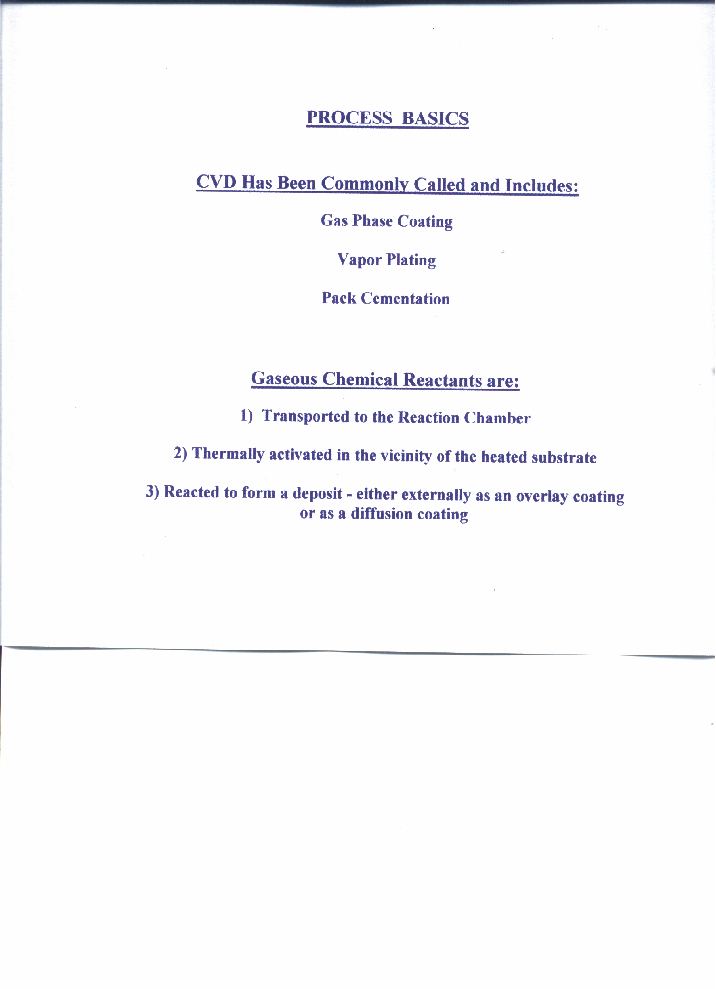

Information on Diffusion Coatings by Pack and above the pack.

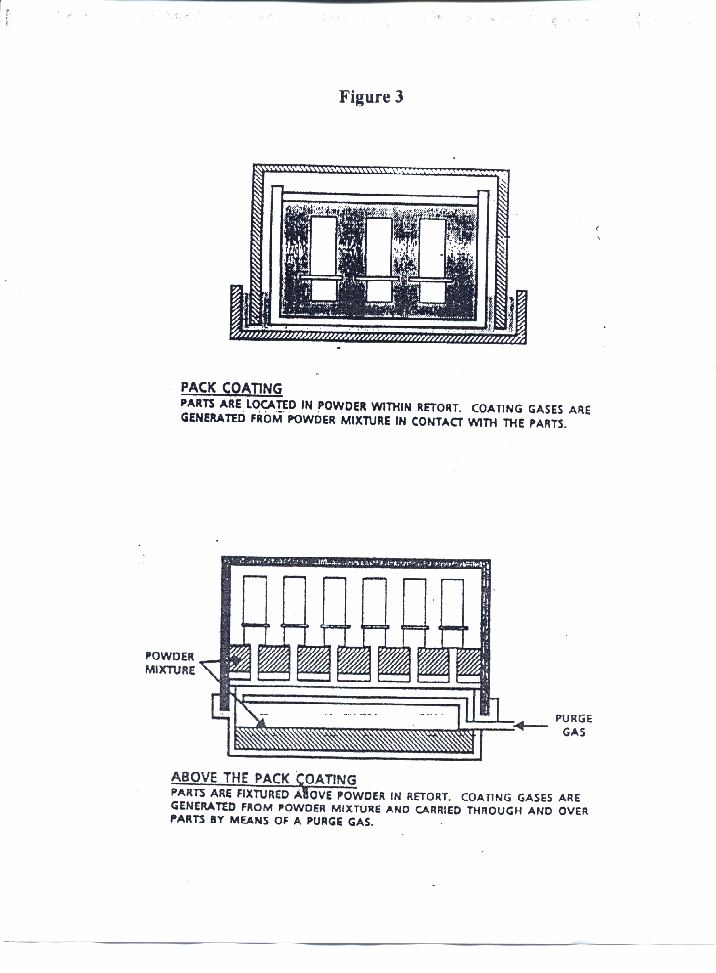

Pack coatings typically are external only and result from burying the component in a powder mix. Gas phase or above the pack techniques do NOT require contact between the part and the powder mix. Instead, a gas is generated.

|

Gas Phase / CVD Aluminizing

CrAl is used to activate AlF3. Coatings can be both Internal as well as External.

Gas Phase / CVD Aluminizing

CrAl is used to activate AlF3. Coatings can be both Internal as well as External. |

Typical Schematics for pack and Above the Pack

Typical Schematics for pack and Above the Pack

|

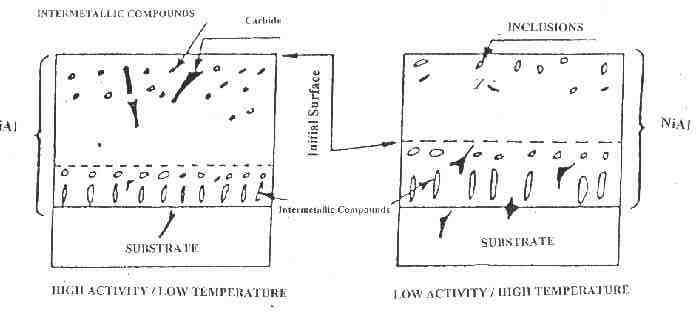

Low Temperature / High Activity vs High Temperature / Low Activity

There are subtle differences but for a LTHA coatings, diffusion of aluminide is all inward while for a HTLA, Nickel diffuses outward and typically the coating is about 35% inward and 65% outward.

Low Temperature / High Activity vs High Temperature / Low Activity

There are subtle differences but for a LTHA coatings, diffusion of aluminide is all inward while for a HTLA, Nickel diffuses outward and typically the coating is about 35% inward and 65% outward. |

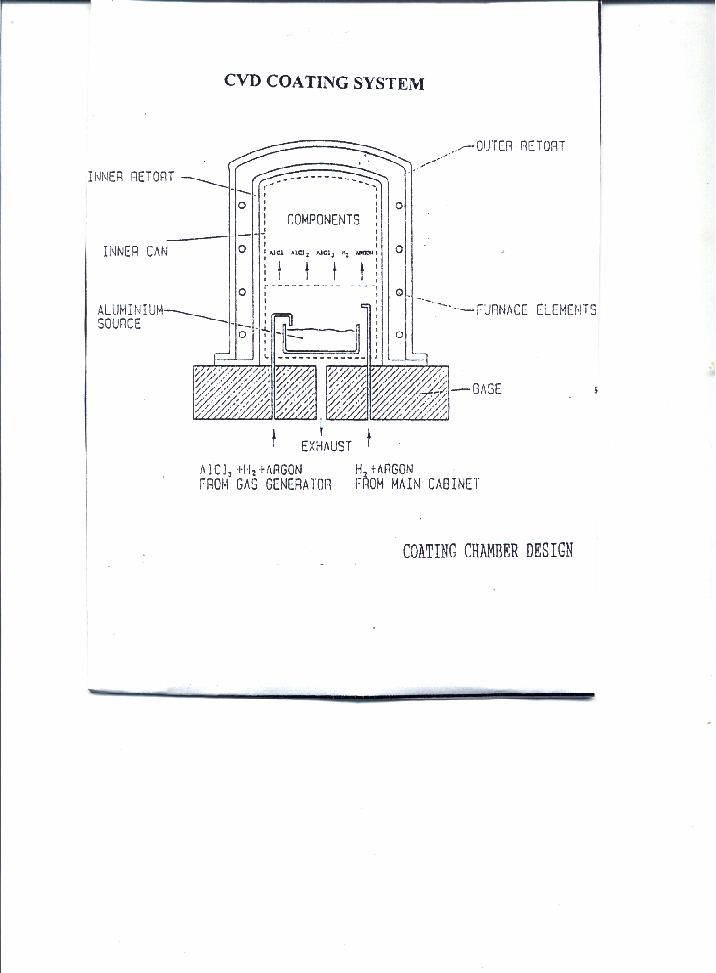

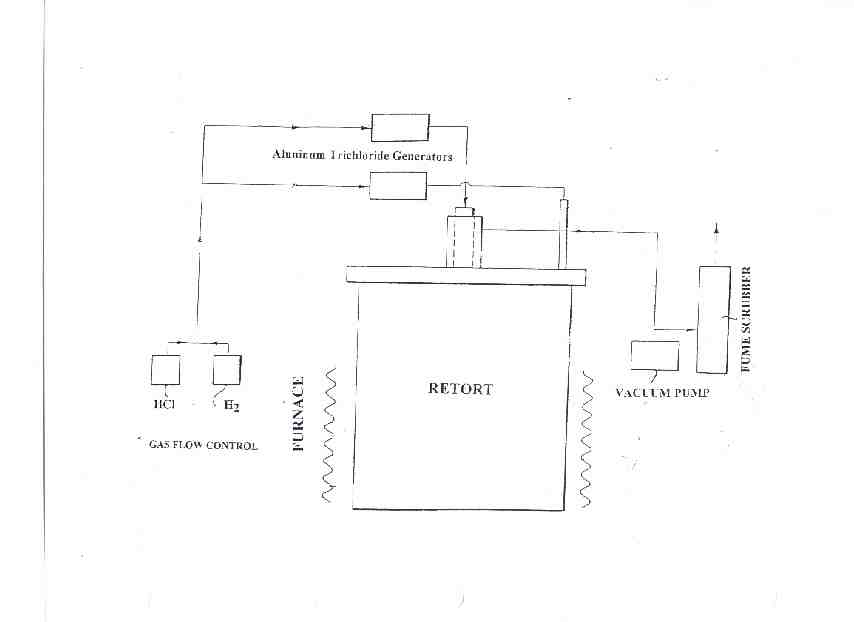

The above CVD system uses a molten aluminum pool.

The molten pool dissasociates the AlCl3 to the more reactive and unstable mono chlorides.

The above CVD system uses a molten aluminum pool.

The molten pool dissasociates the AlCl3 to the more reactive and unstable mono chlorides. |

Simple CVD Schematic

Simple CVD Schematic

|

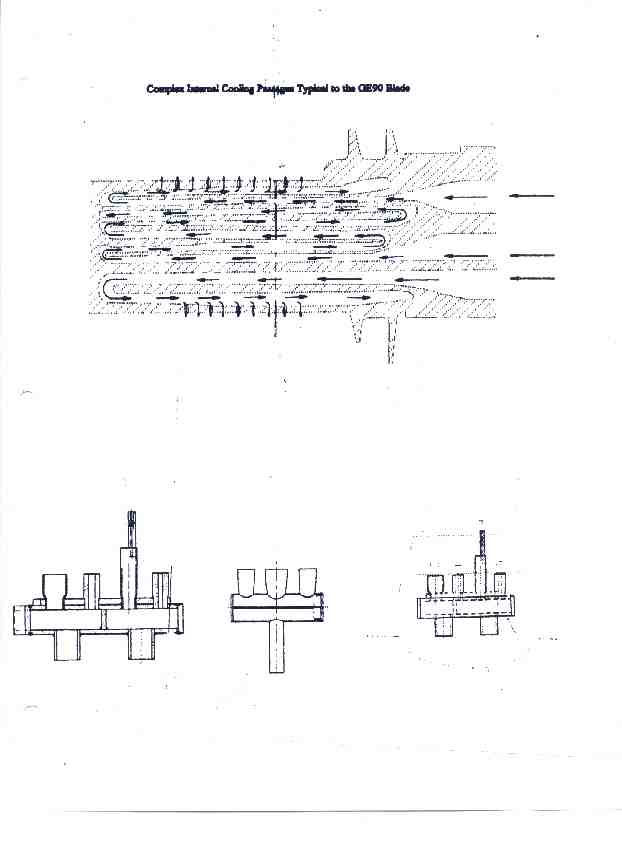

Flow Tubes are used to bring the coating gases into the part.

The gas tubes can be designed to input a more or less correct amount of gas into each pathway.

Flow Tubes are used to bring the coating gases into the part.

The gas tubes can be designed to input a more or less correct amount of gas into each pathway. |

Process Basics

Process Basics

|